Maximum force, precision and duration for every industrial application.

Realized with high-resistance materials, and used for lifts, handling and control applications, hydraulic pistons lead to long-lasting performances. Thanks to designs that can be customized and specific configurations, the cylinders meet the demands of every project, ensuring maximum adaptability and impeccable functioning.

With our configurator, you can customize every detail of your hydraulic cylinder, choosing its dimensions, materials, and characteristics to best meet your production needs.

Tie rod hydraulic cylinders compliant with ISO 6020/2.

Operating pressure up to 160 bar.

Bore sizes from 25 to 200 mm.

Configure

Tie rod hydraulic cylinders compliant with ISO 6020/2, equipped with external magnetic sensors for piston detection.

Operating pressure up to 160 bar.

Bore sizes from 25 to 125 mm.

Configure

Hydraulic cylinders with counterflanges compliant with ISO 6020/2.

Particularly suitable for strokes over 2000 mm and operating pressure up to 210 bar.

Bore sizes from 50 to 200 mm.

Configure

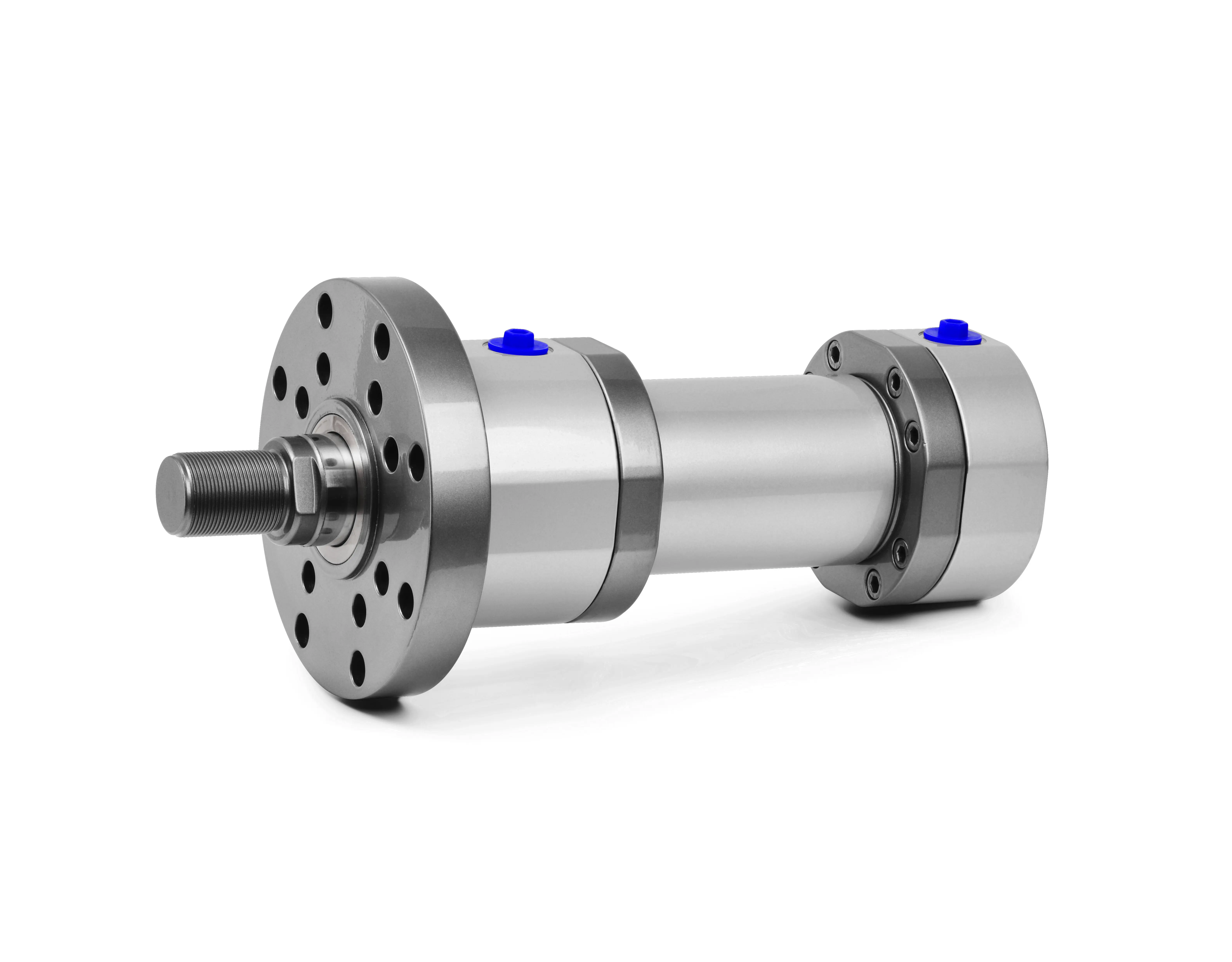

Heavy-duty hydraulic cylinders compliant with ISO 6022, with bronze guides for the piston and rod to ensure high performance and durability.

Operating pressure up to 250 bar.

Bore sizes from 50 to 320 mm.

Configure

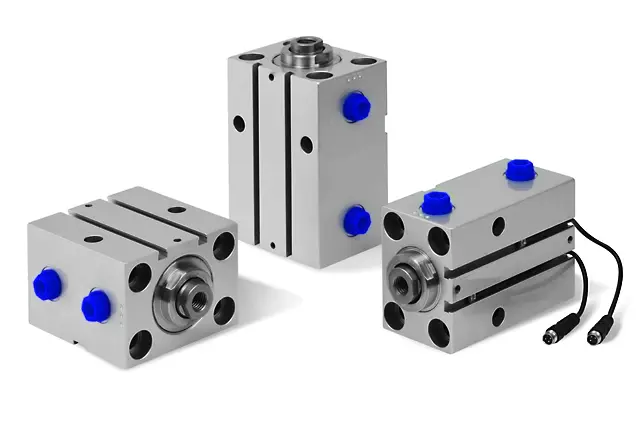

Compact double-acting hydraulic cylinders made of high-strength aluminum with anti-wear treatment.

Operating pressure up to 160 bar.

Bore sizes from 25 to 100 mm.

Configure

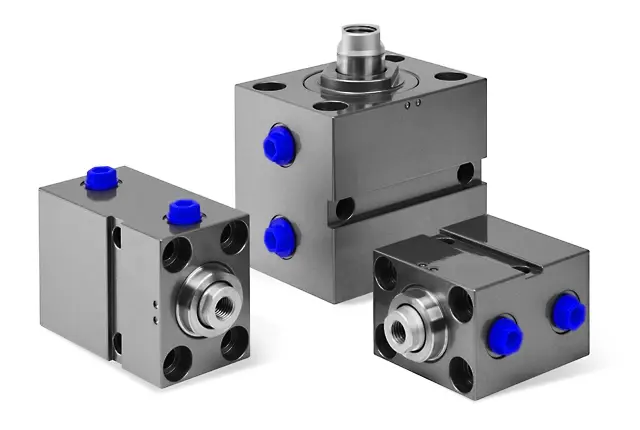

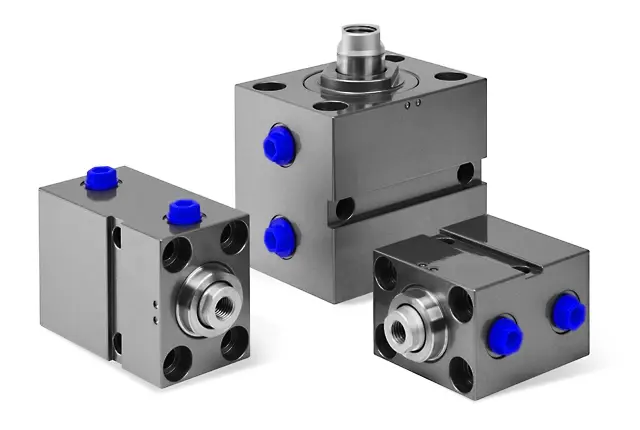

Compact double-acting hydraulic cylinders made of steel for heavy-duty applications.

Operating pressure up to 250 bar.

Bore sizes from 25 to 100 mm.

Configure

Compact double-acting hydraulic cylinders made of high-strength aluminum with anti-wear treatment.

Operating pressure up to 160 bar.

Bore sizes from 25 to 100 mm.

Configure

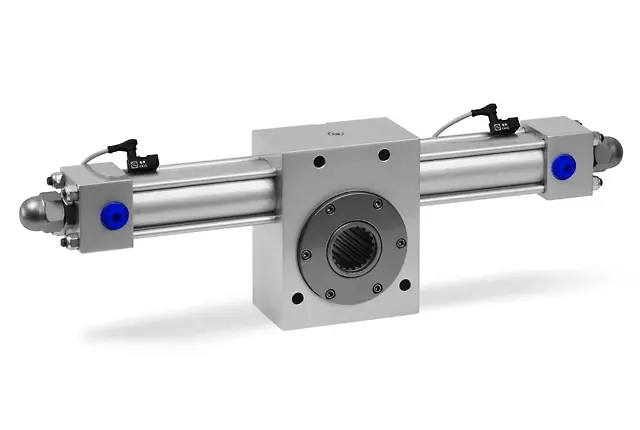

Rotary actuators for torques from 6 to 120 daNm, rotations between 90° and 270°, operated via a hydraulic cylinder and a rack.

Equipped with adjustable brakes and adjustable end stops.

Configure

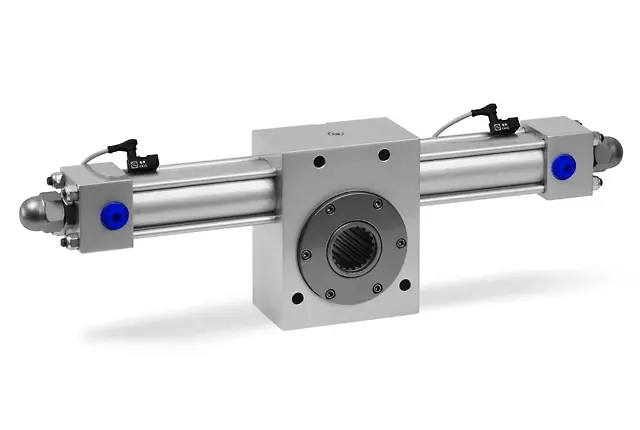

Rotary actuators for torques from 6 to 120 daNm, rotations between 90° and 270°, operated via a hydraulic cylinder and a rack.

Equipped with adjustable brakes and adjustable end stops.

With magnetic position sensors.

Configure

Rod end bearings or clevis terminals with pin.

Male terminals or hammerhead terminals.

Hinged supports, straight supports, or pairs of supports for pins.

The ISO 6020/2 MD tie rod and MP compact magnetic cylinders require their sensors for optimal performance.

To save time and oil, we have all the replacement seals ready for your cylinders.

Configure

Back Back

Celyon offers a complete service for the realization of hydraulic cylinders that includes designing, production, assemblage, installation supervision and post-sale maintanance. We design standard and customized solutions, ensuring products that are ready for use, capable of meeting the most varied needs of production.

The hydraulic cylinders offer great performances with minimum maintenance, increasing efficiency and productivity. Thanks to their versatility, they find application in many fields, ensuring precision and reliability.

High performances for every application.

Designed for long-term use.

Customized configuration for every demand.

Do you need a product or consultancy?

We’re here to help you choose the most suitable hydraulic cylinders for your needs.