Our types of

lubrication systems

We design, produce and install lubrication systems for different industrial application, offering customized high-performing solutions.

A dual-line grease lubrication systems is ideal for large-sized machines that work in difficult conditions, like in the paper and steel industries. Among its main advantages: the use of high pressures, the ease of expansion and the operational continuity, even in case of malfunctioning.

Usage to high pressures

it guarantees an even distribution even if in extreme conditions, ensuring reliable performances even in challenging contexts.

System’s expansion or editing

the system can be expanded without interrupting the operations, adapting quickly to new needs.

Business Continuity

it ensures operational continuity even in case of local malfunctioning, reducing to the minimum down time.

Usage to high pressures

it guarantees an even distribution even if in extreme conditions, ensuring reliable performances even in challenging contexts.

System’s expansion or editing

the system can be expanded without interrupting the operations, adapting quickly to new needs.

Business Continuity

it ensures operational continuity even in case of local malfunctioning, reducing to the minimum down time.

The progressive system is perfect for one-way total systems, guaranteeing reliability and flexibility. It can be designed as a system that is divided into areas, especially when irregular conditions of the cycle are demanded for different parts of the machine, and it allows to calculate the dispensing of the necessary quantity of lubricant in an editable and accurate way.

Usage to high pressures

it supports complex working conditions, with an even and controlled distribution of lubricant.

Modularity

it allows quick editing without interrupting the working process, offering simplified management that can be customized.

Saving

it reduces the operational costs thanks to an optimized designing and it makes its maintenance more efficient and less complicated

Usage to high pressures

it supports complex working conditions, with an even and controlled distribution of lubricant.

Modularity

it allows quick editing without interrupting the working process, offering simplified management that can be customized.

Saving

it reduces the operational costs thanks to an optimized designing and it makes its maintenance more efficient and less complicated

Particularly fit for small-sized machines, it offers a precise dosage of lubrication (continuous or discontinuous). The dosers can be installed directly on the bearing and they balance the pressure on the distribution line, diving the oil from the pump to the different lubrication points.

Accurate dosage

it distributes oil with preciseness, regardless of viscosity, temperature or pressure, enhancing the system’s efficiency.

Adaptability

it integrates easily in different applications thanks to the possibility of combining the threaded extremities with special converters, meeting every demand.

Simple installation

it allows a quick and modifiable configuration, reducing implementation time.

Accurate dosage

it distributes oil with preciseness, regardless of viscosity, temperature or pressure, enhancing the system’s efficiency.

Adaptability

it integrates easily in different applications thanks to the possibility of combining the threaded extremities with special converters, meeting every demand.

Simple installation

it allows a quick and modifiable configuration, reducing implementation time.

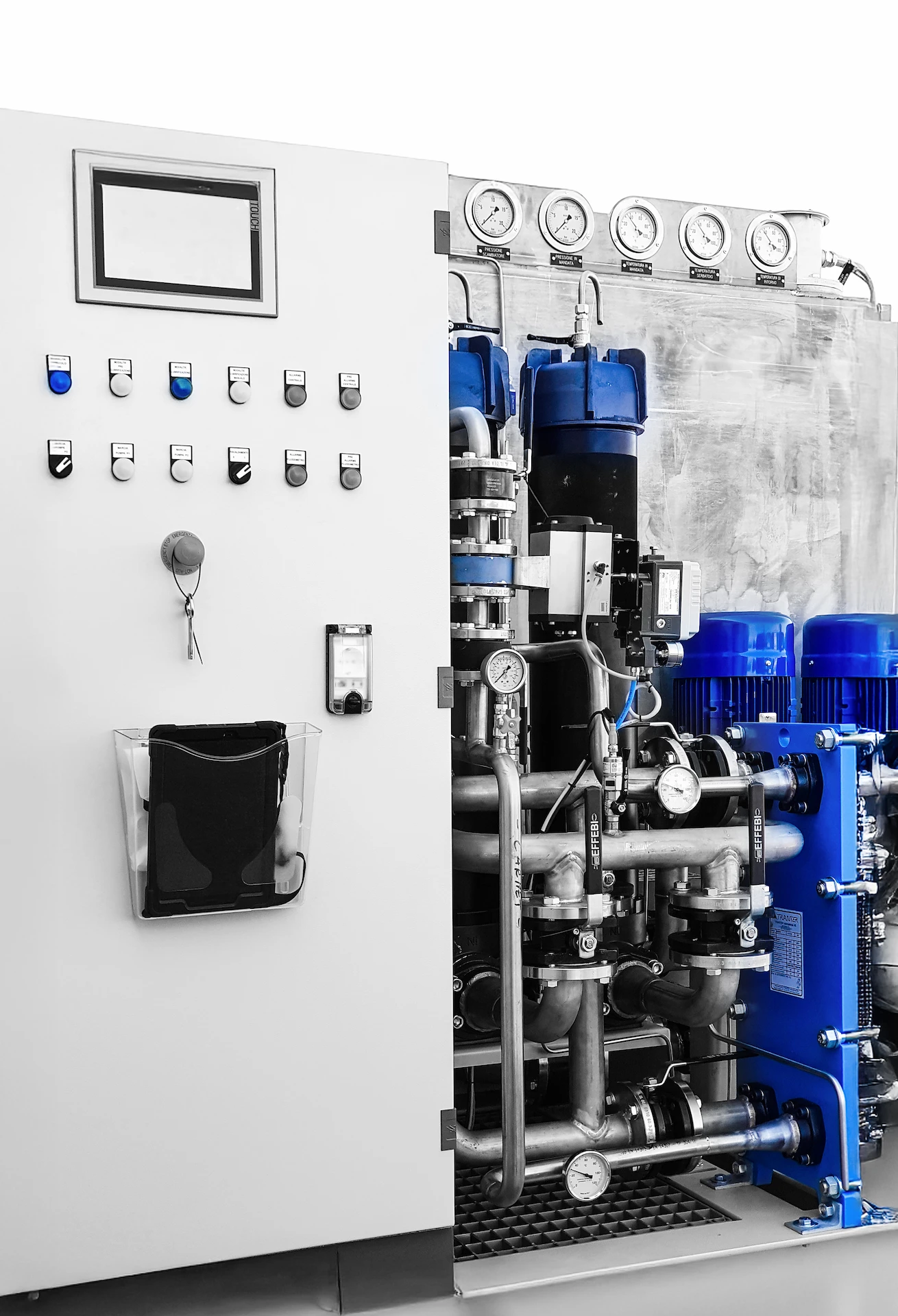

Circulating-oil systems are designed to guarantee continuous and controlled lubrication. They include advanced components to optimize the machine’s efficiency and prevent eventual issues.

Operational efficiency

they optimize the machine’s functioning, increasing the productivity and reducing wastes.

Advanced monitoring

the volumetric flows guarantee a precise control over the lubricant, avoiding inefficiencies.

Failure prevention

solutions designed for minimizing risks and maximizing the efficiency, increasing the overall reliability.

Operational efficiency

they optimize the machine’s functioning, increasing the productivity and reducing wastes.

Advanced monitoring

the volumetric flows guarantee a precise control over the lubricant, avoiding inefficiencies.

Failure prevention

solutions designed for minimizing risks and maximizing the efficiency, increasing the overall reliability.

Our types of

lubrication systems

We design, produce and install lubrication systems for different industrial application, offering customized high-performing solutions.

01

Dual-line grease lubrication

A dual-line grease lubrication systems is ideal for large-sized machines that work in difficult conditions, like in the paper and steel industries. Among its main advantages: the use of high pressures, the ease of expansion and the operational continuity, even in case of malfunctioning.

The progressive system is perfect for one-way total systems, guaranteeing reliability and flexibility. It can be designed as a system that is divided into areas, especially when irregular conditions of the cycle are demanded for different parts of the machine, and it allows to calculate the dispensing of the necessary quantity of lubricant in an editable and accurate way.

Particularly fit for small-sized machines, it offers a precise dosage of lubrication (continuous or discontinuous). The dosers can be installed directly on the bearing and they balance the pressure on the distribution line, diving the oil from the pump to the different lubrication points.

04

Circulating-oil systems

Circulating-oil systems are designed to guarantee continuous and controlled lubrication. They include advanced components to optimize the machine’s efficiency and prevent eventual issues.